The 10 dB Standard for Underlays: What Does It Mean?

When choosing underlays in the Netherlands, their ability to reduce impact noise is often a key factor. The 10 dB requirement is commonly applied, but why is this standard important? And how can you determine if an underlay meets the 10 dB norm? Below, we explain everything you need to know.

What Is the 10 dB Standard for Underlays?

Noise pollution is a significant concern in modern society, and sound insulation plays a crucial role in minimizing disturbances. A well-chosen flooring and underlay combination can contribute to noise reduction. In the Netherlands, many apartment regulations require the use of an underlay that meets the 10 dB impact sound reduction standard, ensuring less noise disturbance for downstairs neighbors.

Which Values Are Used?

In the flooring industry, two key values are used: ΔIlin and ΔLw. The Netherlands primarily uses ΔIlin values.

- ΔIlin (dBΔL) represents the impact sound reduction of an underlay compared to a bare concrete floor.

- A ΔIlin of 10 dB is roughly equivalent to a ΔLw of 21 dB.

Why Is There a 10 dB Standard for Underlays?

Unlike other countries, the Netherlands focuses on measuring low-frequency sounds, as these penetrate floors more easily. This is why the testing standard here covers a wide frequency range, emphasizing low tones.

Underlays are tested in combination with a top floor covering. The entire flooring system is placed on a concrete reference floor, and impact tests are conducted at specific points. The measured improvement in decibels determines whether the underlay meets the 10 dB standard and qualifies for certification.

How Can You Identify a Certified 10 dB Underlay?

The TÜV Rheinland certification is the most recognized label for underlays that meet the 10 dB noise reduction standard. This voluntary certification helps consumers choose the best underlays available.

Certified Underlays

If you live in an apartment, a certified underlay allows you to prove to your Homeowners' Association (VvE) that your flooring meets the 10 dB ΔIlin requirement. Certified underlays are marked with the TÜV Rheinland seal, and their certification can be found in the Certipedia online database.

How Does TÜV Rheinland Test Underlays for the 10 dB Standard?

TÜV Rheinland measures and certifies underlays according to NEN-EN-ISO standards through a four-step process:

Step 1

A sample of the underlay is selected and tested in a specialized laboratory.

Step 2

The sample is analyzed according to specific protocols, and its impact noise reduction is calculated.

Step 3

If the sample meets the requirements, a certificate is issued, and the underlay receives the TÜV quality seal.

Step 4

Certified products undergo periodic inspections. TÜV experts randomly test products from the market or conduct production audits to ensure ongoing compliance with the 10 dB standard.

Conclusion

Underlays with the TÜV 10 dB label have been tested in combination with laminate flooring. However, this does not automatically mean that the same underlay will provide 10 dB noise reduction with wooden planks or parquet.

Want to know which Estillon products carry the TÜV label? Check out our product finder below and choose the right underlay for your needs.

On our news page you will find the latest updates about Estillon, innovative developments in the field of subfloors and installation products, and inspiring projects we are working on. Whether you are a professional, distributor or project manager, we will keep you informed of relevant trends and news from the industry.

News

Heatbond seam tape for crisp seams

Want a professional, lasting carpet finish? Discover how Heatbond seam tape ensures crisp seams, long-term stability and a flawless result – even in high-traffic areas.

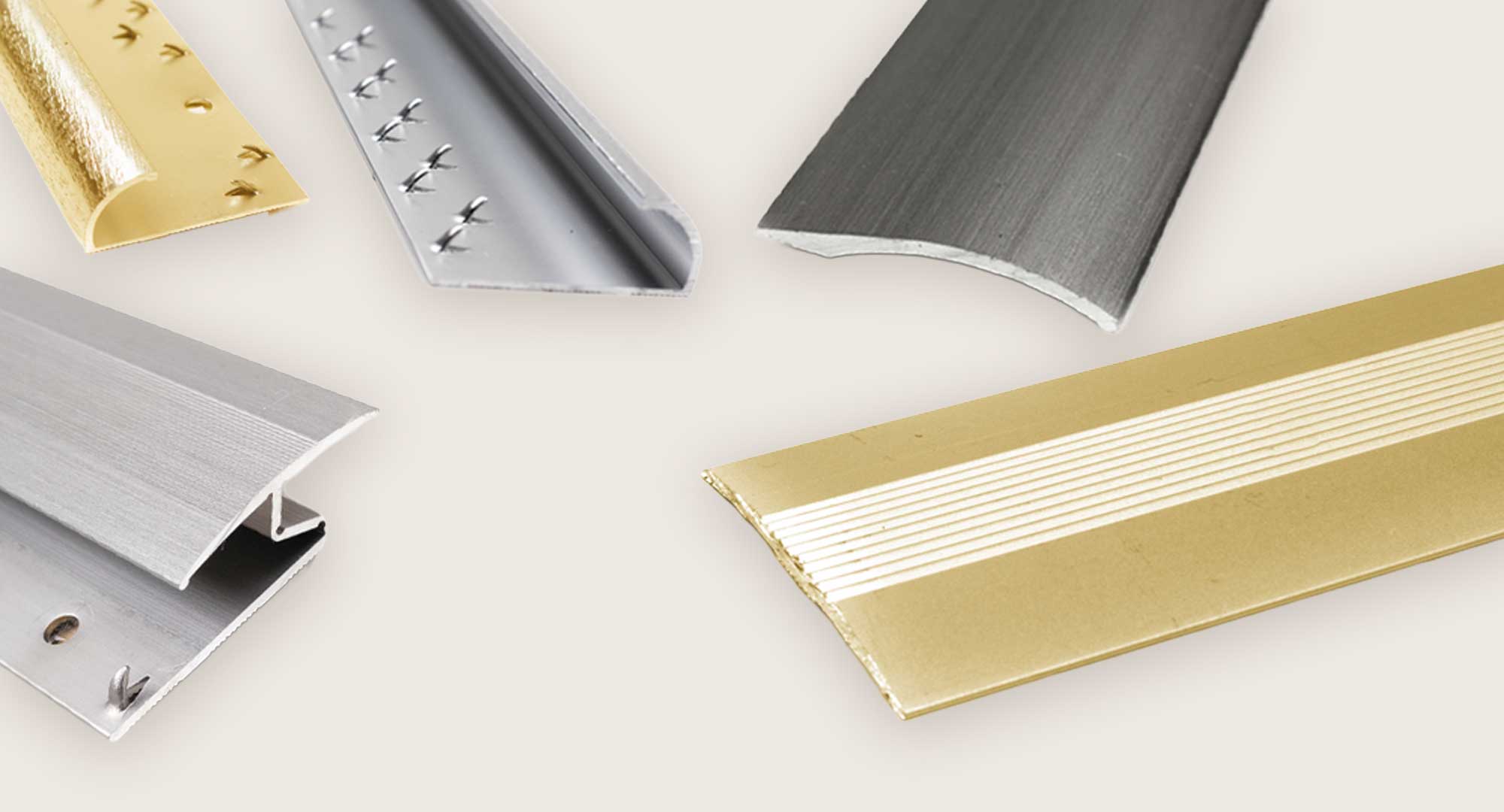

Floor profiles: Clean transitions, strong edges

Discover how the right floor profiles can transform your floor: from neat transitions to a durable finish — read the full blog about achieving a sleek floor finish!

Which Tape is the Best Choice for Your Project?

Are you looking for the right tape for your specific application? In our extensive range, you’ll find the perfect tape for the most common uses.

Estillon at Cruise Ship Interiors Expo Europe 2025

Discover how Estillon makes cruise interiors quieter, more sustainable, and safer. Visit us at Cruise Ship Interiors Expo Europe, Hamburg (stand E72, 3–4 Dec 2025).

Four common misconceptions when choosing an underlay – and how to address them

Misconceptions in underlay choice lead to complaints and failure costs. Pay attention to types of sound, compressive strength, levelling and certification for a solid foundation and guaranteed delivery. Discover how to avoid these pitfalls.

Tredaire Colours Red: The ultimate underlay for soft comfort

Tredaire Colours Red is a premium 11.4 mm sponge rubber underlay designed for domestic use, offering luxurious comfort, warmth, and sound insulation (46 dB ∆LW). Ideal for bedrooms and living areas, it creates a soft, resilient base under carpets, extending their lifespan and enhancing everyday comfort. This high-quality underlay combines durability with a refined feel, making it the perfect choice for those seeking added comfort, quietness, and elegance in their home.

Tredaire underlay: Feel the difference, make the difference

Tredaire offers durable, comfortable underlays made from 100% recycled PU foam. They extend carpet life, reduce noise, and improve energy efficiency. Perfect for offices, hotels, and residential spaces. Renu leads the way: 98% recycled, CO₂-neutral, and fully recyclable. With Tredaire, you choose smart comfort and circularity — the perfect foundation for every interior project.

Tredaire: Feels like nothing on Earth

Tredaire underlays offer unparalleled comfort, luxury, and durability—unseen, yet essential. Discover the core values behind this leading brand: softness, technical expertise, sustainability, and stability. Find out why Tredaire is the top choice for homes, hotels, and commercial spaces.

The silent power beneath every carpet: Best Base underlays

Best Base collection: 6 sustainable, 100% recycled PU underlays in various thicknesses from Estillon, designed to deliver optimal comfort, insulation, and long-lasting performance beneath any carpet.

Comfort and durability with premium PU underlay

Estillon introduces the premium PU underlay: an innovative solution that combines comfort and sustainability. Made from high-quality materials with excellent thermal and acoustic insulation, this underlay is ideal for projects requiring high standards of comfort and energy efficiency. Suitable for various floor coverings and easy to install, it offers a future-proof choice for professional installers and project planners. Discover how Estillon delivers the perfect foundation with comfort and durability.

Share your project and win a filled tool bag!

Do you work with Estillon products? Then we’ve got great news: every month, you have the chance to win a well-equipped Roberts tool bag worth €230!

IMO-Certified Underlays for Maximum Safety and Performance

Estillon offers IMO-certified underlays for maritime applications. These high-quality underlays meet strict fire safety standards and deliver durable, reliable performance at sea. From lightweight, comfortable options to robust solutions for heavy use – always with maximum safety.

Search

No results found.